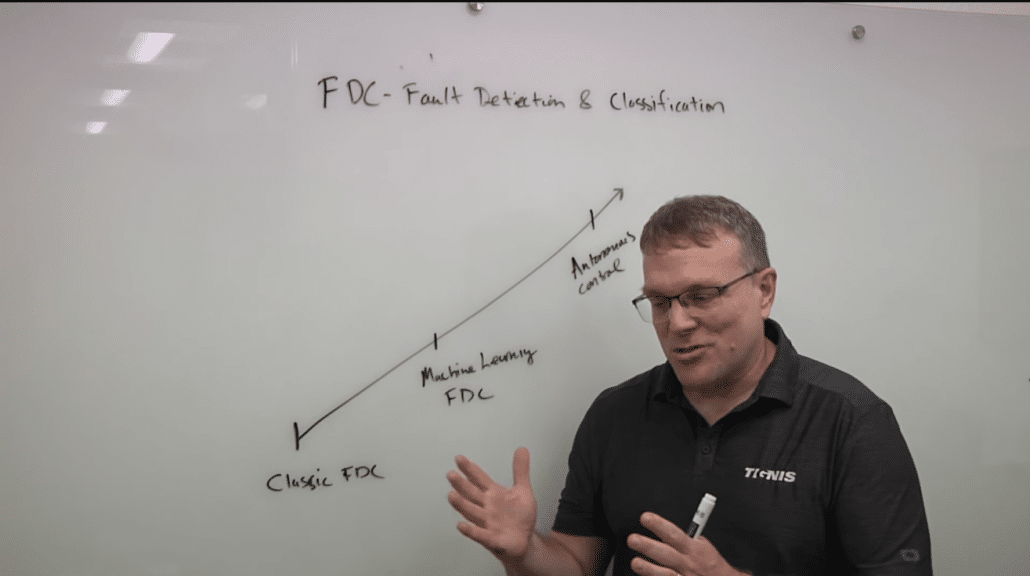

Using AI For Fault Detection And Classification In Semiconductor Manufacturing

Classic fault detection and classification has some classic problems. It’s reactive, time-consuming to set up, and any product change involves significant man-hours. Even then, it still misses a lot of problems, which result in scrap. This is where machine learning can excel, because it can sift through huge amounts of data from thousands of sensors and find outliers and patterns. But there’s a big difference between supervised FDC and unsupervised. Jon Herlocker, VP & General Manager of Tignis, A Cohu Analytics Solution, talks with Semiconductor Engineering about the limitations of supervised FDC, which relies on previous faults, and why unsupervised FDC is necessary to reduce scrap and predict where failures will occur. [This is the third part in a seven-part series on AI in manufacturing.]