Consumer Expertise

Helping customers bring innovative products to the world.

Helping customers bring innovative products to the world.

High throughput testing, handling, and interface solutions meeting the cost challenges of the consumer market.

Fitness Wearables

Set-top Box

Voice User Interface

FPD driver test capability available on a low-cost, air-cooled universal test platform.

High throughput testing, handling, and interface solutions meeting the cost challenges of the consumer market.

Kelvin contact solutions that scale to high power and small footprint to enable high test site density.

Best-in-class precision analog source and measurement technology.

Low-cost configurable turret test handlers.

Unique NV-Core advanced vision with infrared technology to inspect below the silicon surface and metrology tools to distinguish micro-cracks from cosmetic issues.

Loader/Unloader

Loader/UnloaderNY32-LU – is a highly efficient and flexible loading/unloading of InCarrier, including vision inspection and final packaging. Controlled and sensitive device handling with Cohu’s high precision turret and enhanced vision capabilities with NV-Core Inspection System. With our scalable concept, one system could be used as a Loader and Unloader or depending on the desired output, a dedicated Loading or Unloading system can be configured and optimized.

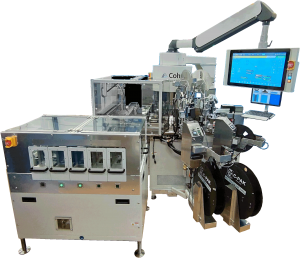

High-Speed Laser Mark Handler

High-Speed Laser Mark HandlerMCT MH-3300 – designed for marketing of 2DiD codes on the lead frame in support of strip testing, marking of reject devices, and final package marketing in strip test or assembly operations.

High-Throughput Film Frame Handler

High-Throughput Film Frame HandlerMCT FH-1200 – designed to handle leadless devices mounted on film frame, such as QFN, DFN, WLCSP, BGA, µBGA and eWLB packages.

We offer innovative concepts for the automotive MEMS market; magnetic, inertial, pressure, microphone, optical, humidity and gas sensor test. Cohu MEMS solutions combine the advantages of well-established and production-proven tri-temp test handling equipment with innovative concepts to meet the special requirements of the MEMS market.

Sense+ – next-generation MEMS sensor test platform allows for significant improvement in test accuracy, parallelism for a lower cost of test, and the ability to handle and inspection, small delicate sensors. Fully configured Sense+ delivers a one-pass automated test, inspection, and metrology for the most complex MEMS devices including <1 mm WLCSP.

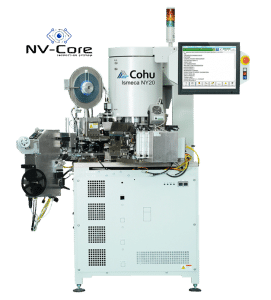

Highest Throughput for Fragile Devices

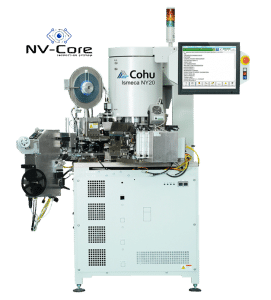

Highest Throughput for Fragile DevicesIsmeca NY20 – 20-position turret platform for semiconductors test, inspection and packaging, providing the highest quality yield and throughput. It integrates innovative hardware and software technology such as intelligent features that enable extended autonomous operation and productivity. The NY20 also integrates with Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection and micro-crack detection algorithm with a high-resolution camera.

Highest Demanding Finishing Processes

Highest Demanding Finishing ProcessesIsmeca NY32 – 32-position turret platform for semiconductors test, inspection and packaging, providing the highest process integration capabilities. Integrating innovative hardware and software technology such as intelligent features that enable extended autonomous operation and productivity. The NY32 also integrates Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection and micro-crack detection algorithm with a high-resolution camera.

Flexible Test and Scan Solution for FFC Devices

Flexible Test and Scan Solution for FFC DevicesIsmeca NY32W – 32-position turret platform for semiconductors on film-frame wafer media, providing the highest inspection yield. Integrating innovative hardware and software technologies such as intelligent features that enable extended autonomous operation and productivity. The NY32W also integrates Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection, sidewall micro-crack detection, and infrared inspection technology for sub-surface defect detection.

Market Leading Inspection Yield with Uncompromised Throughput

Market Leading Inspection Yield with Uncompromised ThroughputNeon – can handle fragile wafer level chip scale products at high speed, maintaining high operational efficiency while inspecting small devices down to 0.4 x 0.2 mm in size. It features extended process integration capabilities and can be configured with infrared and visual micro-scale defect inspection modules. It is also equipped with an external loader unloader to integrate with factory robots for customers adopting Industry 4.0 initiatives.

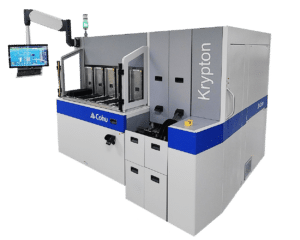

Tray to Tray and Tray to Tape

Tray to Tray and Tray to TapeKrypton – Full 6-sided inspection & metrology system for high-end semiconductor packages, based on its unique racetrack architecture combined with Cohu’s sophisticated NV-Core vision technology, it delivers state-of-theart inspection with up to 30% higher throughput and uptime compared to existing systems.

Ismeca NY20 – 20-position turret platform for semiconductors test, inspection and packaging, providing the highest quality yield and throughput. It integrates innovative hardware and software technology such as intelligent features that enable extended autonomous operation and productivity. The NY20 also integrates with Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection and micro-crack detection algorithm with a high-resolution camera.

Ismeca NY20 – 20-position turret platform for semiconductors test, inspection and packaging, providing the highest quality yield and throughput. It integrates innovative hardware and software technology such as intelligent features that enable extended autonomous operation and productivity. The NY20 also integrates with Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection and micro-crack detection algorithm with a high-resolution camera.

Highest Demanding Finishing Processes

Highest Demanding Finishing ProcessesIsmeca NY32 – 32-position turret platform for semiconductors test, inspection and packaging, providing the highest process integration capabilities. Integrating innovative hardware and software technology such as intelligent features that enable extended autonomous operation and productivity. The NY32 also integrates Cohu’s latest advanced inspection technologies such as 3D Flex for 3-dimensional topographic inspection and micro-crack detection algorithm with a high-resolution camera.

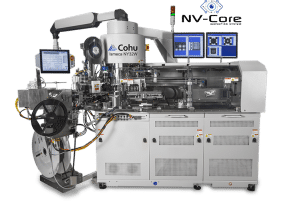

Inspection to serve overall machine performance

Inspection to serve overall machine performanceNV-Core – is Cohu’s unique vision technology, enabling advanced inspection capabilities across Cohu’s handler portfolio. NV-Core latest advance inspection technologies include innovative solution such as, 3D Flex for 3-dimensional topographic inspection, sidewall micro-crack detection, and infrared inspection for sub-surface defect detection. In addition to device quality inspection, by mastering the “all-in-one” solution, Cohu can offer unique capabilities for handler’s diagnostics and alignments, that enable the highest productivity performance.

Flexible, Cost Optimized Test Solutions for the Most Challenging Applications

Flexible, Cost Optimized Test Solutions for the Most Challenging ApplicationsDiamondx – extends Cohu’s low-cost, high-throughput production test solution platforms to high pin count, higher site count wireless, mobility, SOC, Flat Panel Display drivers, Power Management, and microcontrollers. Designed to meet the cost drivers IC companies face, Diamondx extends Cohu’s leadership in lowering the cost of operations.

Changes the Rules of Design Through to Production Test

Changes the Rules of Design Through to Production TestDiamondx DxV – provides full semiconductor ATE performance in a desktop PC footprint. Fully integrated, ultra-compact test system designed to be used in the engineering lab or office. Unlike traditional semiconductor ATE solutions no mainframe, separate workstation, or support cabinets needed. The DxV is completely stand-alone, so it can be placed on a bench or desktop.

Market Leading Test System for High Volume RF PA / FEM, 5G and Mobility Devices

Market Leading Test System for High Volume RF PA / FEM, 5G and Mobility DevicesPAx – flexible architecture allows configurations of a wide range of instruments that are designed to address the test challenges for RF power amplifiers and front-end modules used in cellular and connectivity applications, including WLAN standards up to Wi-Fi 6, 2G to 5G wireless and beyond, Bluetooth and a variety of IoT standards.

Analog and Mixed Signal Devices

Analog and Mixed Signal DevicescPython Kelvin Contactor/Probe Head – provides superior electrical and thermal performance with significant cost savings. This makes cPython Kelvin ideal for lab and high-volume production test of analog and mixed signal integrated circuits – for applications such as power control, A-D and D-A converters, audio, video, power amplifiers, photonics, optical MEMS and sensors. cPython Kelvin probes are electrically isolated and mechanically independent force and sense paths for true Kelvin contact for taking accurate measurements, even under high current conditions.

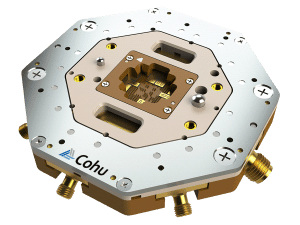

cmWave and mmWave up to 100 GHz

cmWave and mmWave up to 100 GHzxWave Contactor/Probe Head – utilizes patented hybrid contacting technology to optimize RF performance and provide robustness for production testing of the most challenging cmWave and mmWave devices. Inside the xWave contactor are embedded patch antennas and coplanar waveguides for both wireless and wired communication.

ICON Coaxial Contactor – designed specifically for maintaining the native impedance of the device-under-test (DUT) through the contactor to the test system, maximizing high frequency power transfer by minimizing signal reflections (Return Loss).

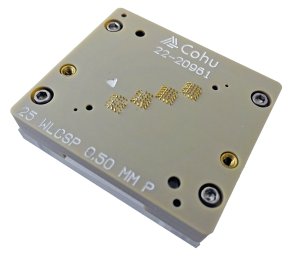

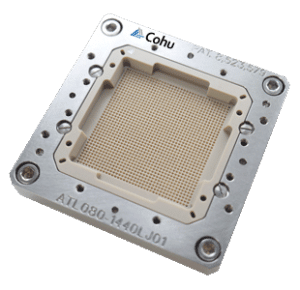

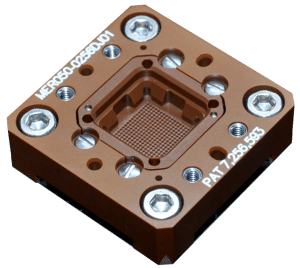

High-End Digital and Large I/O Count Devices

High-End Digital and Large I/O Count DevicesAtlas Contactor/Probe Head – offers electrical performance that allows the customer to test the true performance of the device. Atlas WLCSP test contactors achieve mechanical reliability with a rigid “cruciform” tip applied to Cohu’s QuadTech flat probe technology. The Atlas offers a short electrical path, with lower capacitance and inductance, that is ideal for functional and AC parametric testing of WLCSP devices that require high system bandwidth and throughput gains in large multisite test applications.

High Volume Production Test

High Volume Production TestcBoa Contactors/Probe Head – the solution for contacting high frequency devices for package test or final test at wafer. The robust design and materials of the cBoa probe withstand the rigors of high-volume test by providing longer life and higher yield. The homogeneous DUT side plunger provides longer run times between cleaning and increased probe life.

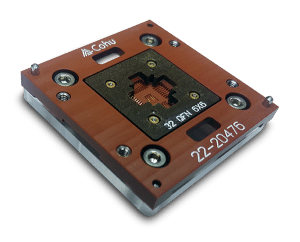

In-Line and Array Packages

In-Line and Array PackagesGemini Kelvin Contactor/Probe Head – provide a first-rate solution that effortlessly makes reliable, true Kelvin contact for high-volume final test of both singulated packages and wafer-level devices. Gemini Kelvin is an ideal solution for devices such as power controllers, A-D and D-A converters, power amplifiers and audio and video circuits.

Mercury Contactor and Probe Head – excellent spring probes for the laboratory though they were designed with the robust qualities needed for high-volume production test. Their unique design ensures excellent plating quality for low, consistent resistance, long life, and high-test yields.

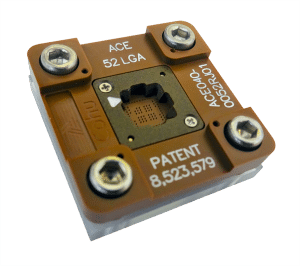

RF Contactor for FBGA and Wafer-Level Packages

RF Contactor for FBGA and Wafer-Level PackagesACE Contactor/Probe Head – offers optimal RF performance for fine pitch FBGA, QFN and wafer-level packages for Power Amplifiers, RF switches and mobile communications. Supporting pitches down to 0.4 mm and superior performance for current consumption, gain, standard deviation, and power efficiency.

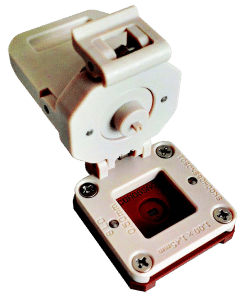

RF High Performance

RF High PerformanceRF Scrub Contactor – innovative design combines an extremely short signal path (0.90mm test height) with high wear resistance pins that can operate in a wide temperature range (-55ºC to +155ºC).

cDragon Spring Probe Contactor – excellent RF performance with low cost of ownership. cDragon pin’s thermal design supports fast temperature control response and stabilization for repeatable at temperature testing of devices in a handler environment.

Complete our contact form.

This website stores cookies on your computer. These cookies are used to improve our website and provide more personalized services to you, both on this website and through other media. To find out more about the cookies we use, please see our Privacy Policy.

Accept All CookiesReview Cookie SettingsAccept Only Essential CookiesWe may request cookies to be set on your device. We use cookies to let us know when you visit our websites, how you interact with us, to enrich your user experience, and to customize your relationship with our website.

Click on the different category headings to find out more. You can also change some of your preferences. Note that blocking some types of cookies may impact your experience on our websites and the services we are able to offer.

These cookies are strictly necessary to provide you with services available through our website and to use some of its features.

Because these cookies are strictly necessary to deliver the website, refusing them will have impact how our site functions. You always can block or delete cookies by changing your browser settings and force blocking all cookies on this website. But this will always prompt you to accept/refuse cookies when revisiting our site.

We fully respect if you want to refuse cookies but to avoid asking you again and again kindly allow us to store a cookie for that. You are free to opt out any time or opt in for other cookies to get a better experience. If you refuse cookies we will remove all set cookies in our domain.

We provide you with a list of stored cookies on your computer in our domain so you can check what we stored. Due to security reasons we are not able to show or modify cookies from other domains. You can check these in your browser security settings.

These cookies collect information that is used either in aggregate form to help us understand how our website is being used or how effective our marketing campaigns are, or to help us customize our website and application for you in order to enhance your experience.

If you do not want that we track your visit to our site you can disable tracking in your browser here:

We also use different external services like Google Webfonts, Google Maps, and external Video providers. Since these providers may collect personal data like your IP address we allow you to block them here. Please be aware that this might heavily reduce the functionality and appearance of our site. Changes will take effect once you reload the page.

Google Webfont Settings:

Google Map Settings:

Google reCaptcha Settings:

Vimeo and Youtube video embeds:

The following cookies are also needed - You can choose if you want to allow them:

You can read about our cookies and privacy settings in detail on our Privacy Policy Page.

Privacy