Horizontal MEMS Cantilever Platform – Scaled and Optimized for Different Current Levels, Device Sizes, and Test Insertions

Built for High Current, Designed for Long Life.

The MAXOR™ Series is Cohu’s standardized family of horizontal MEMS cantilever contactors, engineered to deliver high current capability, long lifetime, and superior electrical performance across wafer‑level, singulated die, and final test insertions. Designed for today’s automotive, power, analog, and wide‑bandgap applications, MAXOR enables customers to increase parallelism, uptime, and test efficiency while simplifying interface selection and lifecycle management.

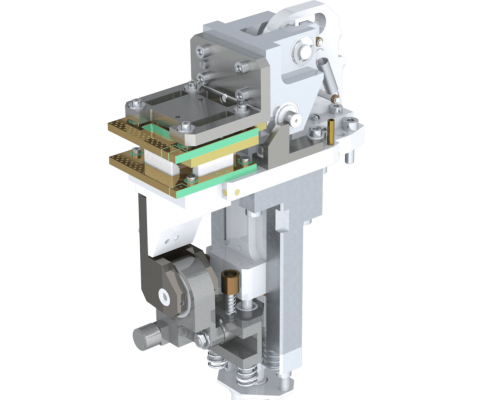

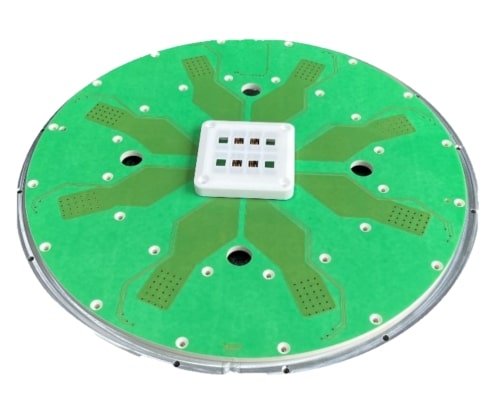

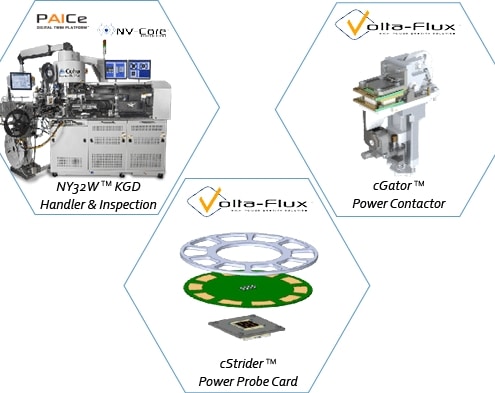

Cohu´s patent pending Volta-Flux™ MEMS probe architecture technology provides stable and low CRES for very challenging high-voltage and high-current requirements.

MAXOR helps semiconductor manufacturers test more devices, more reliably, at lower cost of test.

MAXOR Series combines:

- High current and thermal performance for power‑dense devices

- Exceptional mechanical lifetime to reduce downtime and spares consumption

- Compact, standardized form factors to enable higher handler parallelism

- Broad handler compatibility to simplify global deployments

All delivered within a unified, simplified interface portfolio that reduces customer confusion and accelerates design‑in.

Wide-Bandgap SiC and GaN Devices

High-Voltage and Hot-Test Requirements

Automotive Reliability Standards

Key Features

Performance Where It Matters Most

MAXOR contactors are built to handle high peak and continuous currents, low contact resistance, and extended automotive temperature ranges (‑60°C to +175°C), making them ideal for PMICs, power discretes, automotive ICs, and wide‑bandgap devices.

Long Lifetime = Lower Cost of Test

With lifetimes ranging from >1 million to >5 million insertions depending on configuration, MAXOR reduces:

- Socket change frequency

- Handler downtime

- Spare part consumption

This directly improves overall equipment effectiveness (OEE) and lowers cost of ownership.

Compact Design Enables Higher Parallelism

MAXOR’s small socket footprints and optimized cantilever architectures allow customers to:

- Increase site count on pick‑and‑place, turret, and gravity handlers

- Maximize throughput without expanding handler footprint

This is especially valuable for high‑volume automotive and power test environments.

Standardized Platform, Flexible Applications

The MAXOR family spans:

- Wafer‑level probing (PPC)

- Known Good Die (KGD)

- Die‑level burn‑in (DLBI)

- Final test sockets

All within a common horizontal MEMS cantilever architecture, simplifying qualification, spares strategy, and global manufacturing support.

Future-Ready Solutions Aligned with Electrification, EVs and AI Power Infrastructure

Other Cantilever Solutions

nanoKelvin Contactor

Kelvin test socket for high power plunge-to-board applications

nanoKelvin is a well-established cantilever kelvin contactor with proven performance in the automotive market and further increasing popularity due to the robustness and reliability of the product.

RF Scrub Contactor

Excellent RF performance with low cost of ownership

Extremely short signal path rugged probe with high wear resistance for SO, DFN, and QFN packages

RF Scrub Contactor’s innovative design combines an extremely short signal path (0.90mm test height) with high wear resistance pins that can operate in a wide temperature range (-40º C to +150º C).

The RF Scrub contactor’s long-life, elastomer free design and easy field maintainability makes it an optimal solution for testing of high-performance devices.

The RF Scrub design minimizes load board wear and with the unique pin base material and plating, the cleaning intervals can last up to 100,000 cycles.

The RF Scrub contactor is adaptable to multiple packages (QFN/DFN/MLF, QFP, SO, SOT, TO) and handler platforms making it an ideal low-cost solution for your RF and acoustic applications.

Contact Sales

Complete our contact form.

Expertise

Learn more about our Interface Solutions