ULTRA is a Standardized, Production-Ready Interface Platform – Engineered for Reliability, Repeatability, and Cost-Efficient Test

Standarized, High-Reliability Contactors for Precision & Power Test

The ULTRA® Series is Cohu’s highly standardized interface platform designed to deliver reliable electrical performance, long lifetime, and predictable cost of ownership across a wide range of semiconductor test insertions. With configurations optimized for precision analog, PMIC, small discrete, and power devices, ULTRA provides customers with a drop‑in, production‑ready alternative to conventional spring‑probe and elastomer‑based solutions—without sacrificing performance or reliability

The ULTRA cantilever spring contactors are engineered for high yield and consistent performance in the most demanding environments. Unlike elastomer-based interfaces, ULTRA eliminates performance degradation caused by compression set, temperature, and humidity exposure. ULTRA delivers consistent test performance with simplified design‑in and lower total cost of ownership.

The ULTRA Series combines:

- Highly standardized architectures to minimize customization

- Drop‑in replacement compatibility with legacy probe and socket footprints

- Long, stable mechanical lifetime for high‑volume production

- Broad handler support across pick‑and‑place, turret, gravity, and strip testing

ULTRA is ideal for customers seeking predictability, repeatability, and scalability in mature and high‑volume device segments.

Unlike Elastomer-Based Interfaces ULTRA Series is Unaffected by Compression Set, Temperature, or Humidity

Mixed-Signal

PMIC/Precision Power

Automotive Power

Key Features

Standardization That Simplifies Test

ULTRA is intentionally designed with minimal customization, enabling:

- Faster qualification and design‑in

- Easier global replication

- Lower engineering and validation overhead

This makes ULTRA especially attractive for high‑volume manufacturing environments where consistency matters more than extreme performance tuning.

Drop-In Replacement for Legacy Interfaces

ULTRA solutions are engineered as direct replacements for Spring‑probe sockets and Elastomer‑based contactors

With compatible footprints and form factors, customers can upgrade performance and lifetime without redesigning load boards or handlers.

Customer impact:

- Faster upgrades

- Reduced capital disruption

- Improved uptime with familiar form factors

Reliable Electrical and Mechanical Performance

Across the ULTRA portfolio, customers benefit from:

- Low and stable contact resistance

- Consistent resistance repeatability via one‑piece contact paths

- Extended automotive temperature support (‑60°C to +175°C)

- Typical lifetimes exceeding 1 million insertions

This ensures predictable performance over long production runs

Optimized for Precision, Power and Discrete Devices

The ULTRA family addresses a wide range of applications, including:

- Precision analog and PMIC devices (ULTRA S, ULTRA E)

- Small signal discretes (ULTRA V)

- Power discretes and automotive devices (ULTRA HCI)

Each variant is tuned to balance electrical performance, cost, and durability for its target segment.

ULTRA Series is the Ideal Choice for Cost-Senstive, High-Volume Test Programs

Non-Kelvin, Shortest-Single-Path Solution for Precision Analog & Mixed-Signal Devices

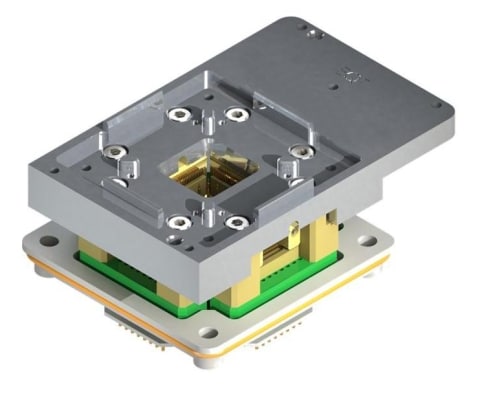

Standardized Kelvin Platform for Automotive and Power Discrete Devices

Drop-In Kelvin Contactor for PMIC and Precision Power Test.

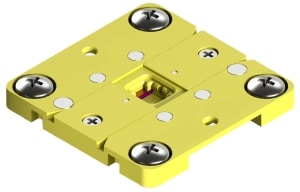

ULTRA HCI is a Kelvin contactor optimized for power discrete and automotive applications, balancing high‑current capability with cost‑efficient standardization. Featuring a one‑piece contact path and economical finger‑replacement concept, ULTRA HCI delivers reliable, repeatable performance in demanding production environments.

ULTRA HCI is ideal for customers who require automotive‑grade reliability and Kelvin accuracy, but prefer a highly standardized, lower‑customization solution compared to performance‑optimized platforms.

Key Benefits

- Consistent resistance repeatability via one‑piece contact design

- Cost‑efficient maintenance with simplified replacement concept

- Automotive temperature range support (‑60°C to +175°C)

- Compatible with multiple handler platforms, including strip test

- Proven solution for high‑volume automotive power device testing

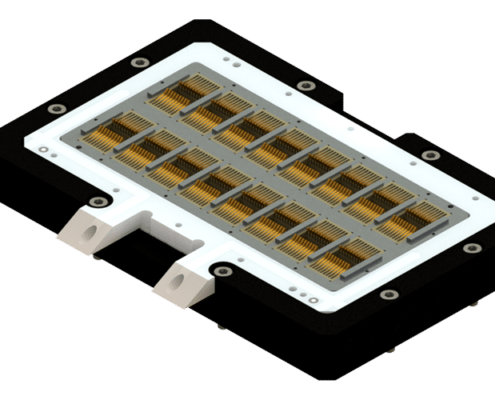

Kelvin, Drop-In Replacement for Spring-Probe Sockets in PMIC & Precision Power Applications

Drop-In Kelvin Contactor for PMIC and Precision Power Test.

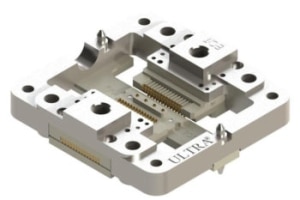

ULTRA V is a Kelvin contactor engineered as a direct replacement for traditional spring‑probe sockets, delivering superior electrical stability, longer lifetime, and reduced cost of ownership—without requiring load board or handler redesign. It is optimized for PMIC, precision analog, and small power devices where repeatable measurements and production efficiency are critical.

ULTRA V enables customers to upgrade legacy probe‑based interfaces with a standardized cantilever solution that improves uptime and electrical performance while preserving existing test infrastructure.

Key Benefits

- Drop‑in compatibility with spring‑probe footprints

- Low and stable contact resistance for accurate Kelvin measurements

- Long mechanical lifetime (>1M insertions) to reduce downtime

- Compact footprint enabling higher handler parallelism

- Automotive temperature range support (‑60°C to +175°C)

Enhanced Non-Kelvin Contactor for Analog & MCU Test with Improved Pad-Wetting and Thermal Stability

Precision Non‑Kelvin Contactor for Analog & Microcontroller Test

ULTRA E is a non‑Kelvin, shortest‑signal‑path contactor designed for precision analog, microcontroller, and mixed‑signal devices where signal integrity, thermal stability, and mechanical reliability are paramount. Its stationary board contact design eliminates elastomers, extending lifetime and improving test consistency in high‑volume environments.

ULTRA E delivers clean signal performance and long‑term stability for customers who need a cost‑efficient, production‑ready alternative to elastomer‑based sockets—without sacrificing electrical accuracy.

Key Benefits

- Shortest signal path for improved signal integrity

- No‑elastomer design reduces wear and performance drift

- Precision thermal test capability across automotive temperature ranges

- Long, predictable lifetime for high‑volume production

- Standardized design simplifies qualification and global deployment

ULTRA Series is the Ideal Choice for Cost-Senstive, High-Volume Test Programs

Markets

Contact Sales

Complete our contact form.

Expertise

Learn more about our Interface Solutions