We are always keeping an eye on news surrounding digital twins, machine learning, data analytics and more. This month our team has been discussing big ideas surrounding Industry 4.0 and what it takes to build a reliability-based maintenance system. Here are a few articles that we found especially interesting during the month of April.

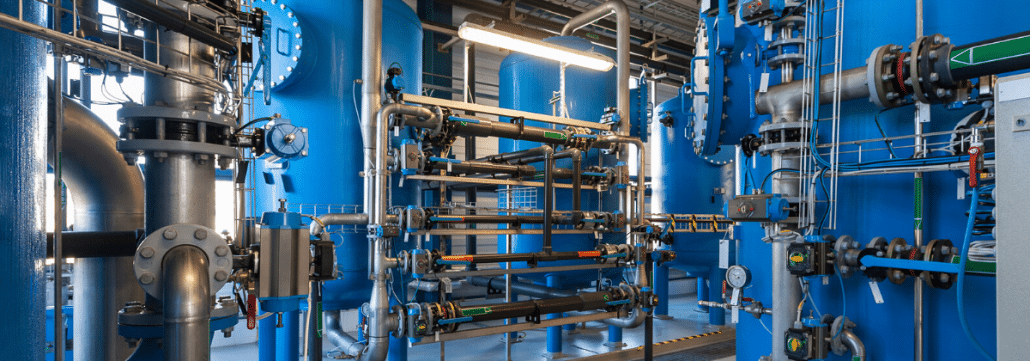

Digital Twins for Managing Water Infrastructure – Water World

Water World magazine had a great article on digitizing data to “help utilities get the most out of their data to improve their decision-making, efficiency, and service.” The article addresses the challenges of data isolated in disconnected IT solutions, spreadsheets and paper records – as well as solutions such as digital twins being adopted by progressive water utilities.

Making the Move to Industry 4.0 – MachineDesign

This article from MachineDesign touches on several key topics within Industry 4.0 – Industrial ethernet deployment, security, and handling large amounts of data. Exploring the benefits of automation, the author observes, “Today, autonomous systems are more interconnected, communicating, analyzing and interpreting data to let managers intelligently decide and act in other areas of the factory.”

7 Steps for Implementing Reliability-based Maintenance – Reliable Plant

Reliable Plant identified 7 key steps to building a reliability-based maintenance program. Here’s a valuable excerpt from the article: “Manufacturers are turning to reliability-based maintenance (RBM) more and more, using RBM as a strategy to help maintain valuable plant assets and eliminate the costly adverse impacts of performance issues like delays and unexpected downtime.”

Augmented Intelligence Webinar – Tignis CEO, Jon Herlocker

Our CEO, Jon Herlocker, joined forces with InfluxData for a webinar surrounding real-time data combined with machine learning. If you’re curious about how Tignis is architected, this is an excellent resource to learn more about the Tignis condition monitoring and analytics solution.