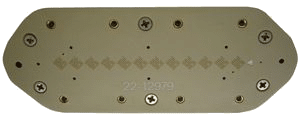

Optimal Performance for Large I/O Count Devices and High-End Digital

QuadTech probe solution with cruciform tip strength that stands up to lateral force without bending, plus an enhanced compliance window to accommodate package stack height tolerance.

Atlas offers electrical performance that allows the customer to test to the true performance of the device. Atlas WLCSP test contactors achieve mechanical reliability with a rigid “cruciform” tip applied to Cohu’s QuadTech flat probe technology. The Atlas offers a short electrical path, with lower capacitance and inductance, that is ideal for functional and AC parametric testing of WLCSP devices that require high system bandwidth and throughput gains in large multisite test applications.

The cruciform tip provides increased tip rigidity with a much greater immunity to breakage. The advantages for the customer include increased run times between contactor cleaning, increased probe life, increased yield, and reduced system down time for contactor maintenance.